Separation

Extraction module

Extraction module using a medium in a supercritical state.

The extractor is an innovative device used to extract dry goods. The process uses a circulating solvent system, e.g.: CO2 in a supercritical state, flowing through baskets filled with a material being extracted. The use of a supercritical gas eliminates the need for toxic solvents, trace amounts of which can remain in the product. Depending on the pressure set, different extract fractions can be taken. The CO2 recirculation system minimises eluent use and protects the environment.

- maximum operating pressure: up to 900 bar

- working volume: 3 × 10 dm3

- temperature adjustment: up to 80°C

- dosing possible with the entrainer pump

Filter module

The membrane filter press allows the suspension to be separated into liquid and solid phases. The segmented design allows for further processing of both the filtrate and the filter cake. It is possible to use disposable filter pads made to the customer’s order.

- filtration volume: up to 450 dm3

- efficiency up to 1000 dm3/h

- ATEX compliant device

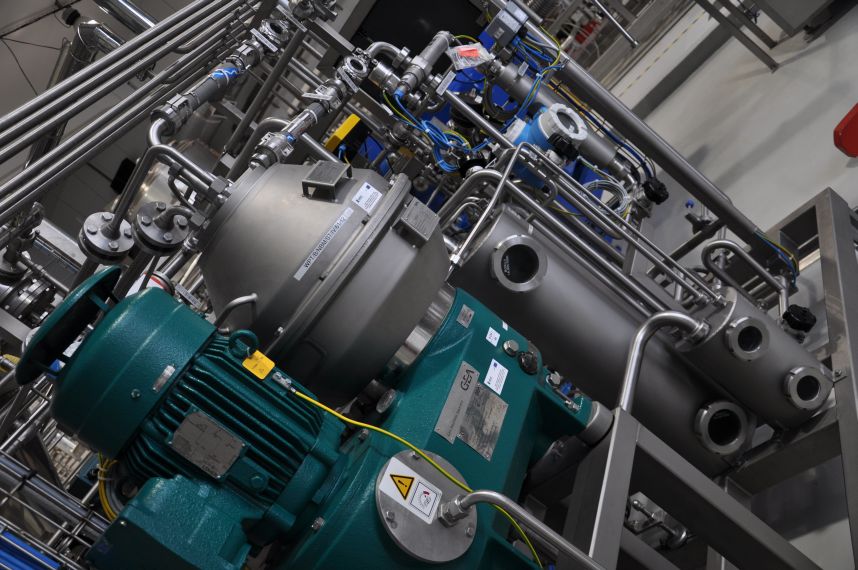

Flow centrifugation module

Flow centrifugation is used to separate liquid-liquid and liquid-solid mixtures of different densities by means of centrifugal force. The heavy phase is removed using water and the device can work in an inert atmosphere.

- efficiency: up to 1000 dm3/h

- Rotational speed: 11,800 RPM

- ATEX compliant device

Vibrating separator

A set of vibrating sieves enables efficient and fast separation while fractionating substances, regardless of whether the product is wet or dry.

- sieve separation limit 25, 125, 200 цm

- efficiency dependent on raw material properties

- ATEX compliant device

Ultrafiltration

Ultrafiltration is a highly efficient process for separation, concentration and purification of macromolecular solutions in industrial manufacturing and scientific research. It is commonly used in the fractionation and concentration of proteins, active substances from fermentation broths and the clarification of fruit and vegetable juices.

- efficiency: up to 1000 dm3/h depending on the raw material

- 19 ceramic membranes (39 channels) with a total surface area of 9.5 m2

- cut-off point: 5 kDa

- temperature range: from 4°C to 80°C

- a chromatographic module capable of being filled with any ion-exchange resin with a volume of 25 dm3

- it is possible to adapt the module by mounting ceramic membranes from 1 kDa to 1.4 µm